How 3D MEP Coordination differs from 2D MEP Coordination?

In this post, we will discuss about the two types of MEP coordination process and their challenges. One is 2D MEP Coordination and another is 3D MEP Coordination.

With the increase of complex MEP systems now-a-days, contracting companies are required to validate design received from design consultants and value engineer the design through spatial coordination and procurement of components to meet design requirements.

The coordination of MEP systems within themselves and with other disciplines including architecture, façade, structure, etc is a challenging and time consuming task. Especially in complex projects with high density of MEP systems. MEP systems shall comply with design requirements and operations criteria avoiding any interference and clashes amongst building systems.

Today almost all construction projects require MEP coordination without which the installation of MEP systems at site would be a difficult task using only the design drawings.

Let’s compare the 2 different methods by which MEP coordination is done.

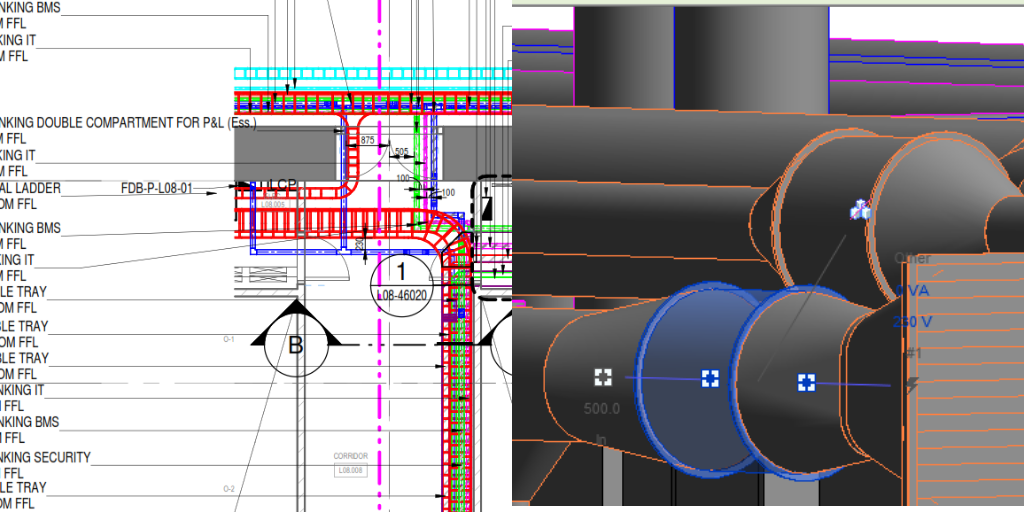

2D MEP Coordination Process

In this 2D MEP Coordination process, the following process is followed:

- Designing of MEP services is done by design consultants,

- Subcontractor then develops design stage drawings received as tender package into shop drawings or develops own set of shop drawings in 2D drawings format,

- 2D drawings includes individual floor plans, combined services drawings (CSDs), sections showing ceiling void spaces, etc,

- Annotations of MEP services within 2D drawings including dimensions, tags and types,

- Main contractor or General contractor ensures that each sub-contractor is creating their drawings based on ceiling void spaces,

- All stakeholders involved in project try to visualize potential clashes manually from individual 2D drawings,

- MEP coordination effectively happens on site and modifications are done to avoid clashes occurring at the time of construction.

2D MEP Coordination Challenges

2D MEP Coordination has its own challenges which are as follows:

- No semi-automated or automated system to identify clashes in MEP systems and design which results in high degree of reliance on the intuition, imagination, technical experience and knowledge of team members involved without experiencing the clashes,

- Visualizing clashes is difficult due to changes in ceiling heights,

- Difficulty in understanding the impact of building services and structural and architectural elements that affects the routing of the MEP systems,

- Appointing third party does not necessarily resolves the issues,

- Designs cannot be easily reviewed or communicated with project team,

- If any design changes are there or procurement changes are there, it becomes very difficult to repeat the 2D MEP Coordination,

- 2D CAD software allows humans to tag differently to a service as the software is not intelligent to detect these types of errors,

- There is no guarantee that 2D MEP Coordination will result in clash free drawings,

- On complex projects, 2D MEP Coordination process requires multiple sections to be viewed which is a time taking task that incurs more expense to contractors.

3D MEP Coordination

This process is more collaborative and provides the ability to communicate effectively as the project progresses by involving 3D visuals that allows everyone to be on same page as compared to everyone trying to visualize on their own using 2D drawings.

The process and benefits of 3D MEP Coordination is as follows:

- Design intent is created which is used as basis to create 3D MEP BIM models,

- Architecture and Structure forms a part of 3D BIM models with which 3D MEP BIM models are superimposed and clashes are checked.

- Once all BIM models are superimposed, it becomes easier to detect clashes using the model geometry intersection method on computers,

- Using the advanced software capability, one can pan and orbit the clash locations into the 3D BIM model to gain in-depth understanding of clashes

- Once clashes are identified, with inputs from design consultants, clashes are then resolved keeping intact the design intent and technical functionality of MEP systems,

- Upon making the clash free BIM models, drawings are then created and extracted from 3D BIM models,

- Drawings involve floor plans and sections which are dynamically linked to each other. That is, if anything is updated in plan, it automatically reflects in section views. This avoids duplicating efforts.

- Drawing annotations are truly a reflection of 3D properties which eliminated error of annotating as compared to 2D processes.

Above we discussed only 3D MEP Coordination process with benefits. However, 3D BIM allows more endless possibilities if used on a project.

At OneClick BIM, we are experts in 2D MEP Coordination and 3D MEP Coordination. However, we always recommend clients and customers towards using 3D MEP Coordination as it is better in all aspects and costs less in terms of efforts and time thereby increasing the overall quality of the building project.

We helped dozens of companies since 2015 in visualizing their BIM / VDC processes utilizing BIM models in regions such as Singapore, UAE, US, UK, Australia, New Zealand, Malaysia, India, and many more. If you are looking for having support in your BIM processes and or BIM manpower requirements, we will listen to your needs and provide you with end to end BIM Solutions. We are there for you to support in your BIM journey.